To Repair or Replace, that is the question. Naturally, the first few questions you need to ask are:

- What is the cost of the motor repair?

- What does a new motor cost?

- Is there a replacement motor readily available?

We review the basics when it comes to repair or replace here, but in this post, we will go through a more thorough decision-making process.

Once you have answered those three basic questions, you need to ask a few, more specific, and equally important questions you need to ask:

- Was the motor appropriate for the application it was being used?

- Was there a Catastrophic Failure?

- What is the condition of the stator?

- What was the root cause of the failure?

- Is there an energy efficiency concern?

- Are there funds/budget for replacing the motor?

- Is there a replacement motor readily available?

Appropriate Motor Application

It is important to go through a series of questions to determine if you have the right motor for how you are using it.

- Did the motor fail because it was the incorrect motor for the application? If it failed due to mechanical overload, you likely require a higher HP motor.

- Is the motor still being used in the same way that it was initially? Is your power supply the same?

Knowing the answers to these questions will help determine if repairing is an option or not.

Was there Catastrophic Failure or Prior Catastrophic Failure?

The first step here is to evaluate the cost of repair compared to the cost of new. If there has been a catastrophic failure it is likely that replacing the motor is most economical, especially if damage is extensive or the suitability for application is in question.

Catastrophic failures do considerable damage to the stator, shaft, bearings, and end brackets and are expensive to repair.

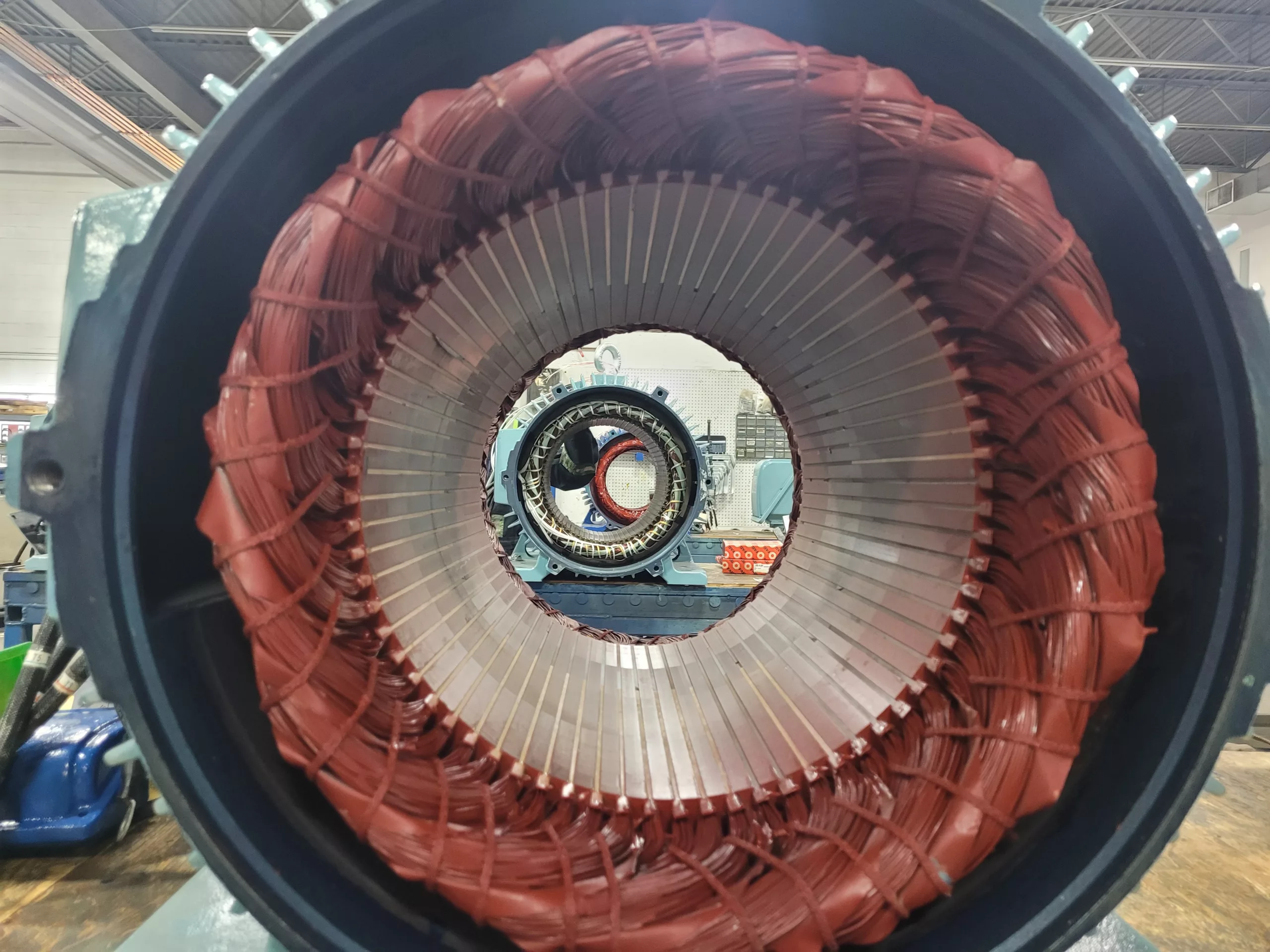

Determine the Stator Core Condition

If Core damage is significant it may be more economical to buy new – Repair of a seriously degraded stator core can be expensive.

- Is there significant damage to the stator?

- Did the motor exceed its rated temperature rise before it failed?

Inspecting other mechanical components:

- The shaft, frame, bearing housing, or other mechanical parts may be damaged beyond repair. Making a new shaft may be an economical option. The cost of buying a new motor may make replacing the motor the logical choice. (Unless the motor is very large or has special features)

Analyze the Root Cause of Failure before you Repair or Replace

This step goes somewhat hand in hand with the question of Application Suitability, however, the root cause of the failure may have nothing to do with the application and rather an issue with operation, maintenance, or power supply (i.e, running the wrong voltage, power surges – in which case using an overload device might be recommended) is the root cause.

Understanding the root cause will save you time, money, and peace of mind in the long run. Once the root cause is identified and addressed will make it an easier decision, coupled with the answers to the other questions, as to whether you should be repairing or replacing.

Consider Energy Efficiency

As Energy Efficiency becomes a bigger focus around the world, so should you in your operation when buying new motors – either replacing an old motor or when buying for a new application. When we talk about energy efficiency in motors we are talking about the efficiency in which electrical energy is converted to mechanical energy. For example, a motor from the 90’s has an efficiency rating of about 92%, and a new IE4 motor is roughly 96% efficient.

To see what this equates to in dollars check out this great read from our friends at ABB!

When assessing an older motor to determine if it should be repaired or replaced, looking at the energy efficiency rating might tell you everything you need to know.

Replacing an older, less efficient motor with a high-efficiency motor can pay for itself over a few years. Especially if the difference in cost between the two options isn’t that great. Conversely, it is possible to repair a high-efficiency motor and maintain its energy efficiency, in some cases the efficiency can actually be improved (when compared to the efficiency prior to repair).

The Impact of Repairing or Rewinding on the Efficiency of Premium Efficiency(IE3) Motors

A study conducted by EASA (Electrical Apparatus Service Association) and AEMT (Association of Electrical and Mechanical Trades) clearly showed that the efficiency of energy efficient and IE2 motors ranging from 7.5 hp to 200 hp (5.5 kW to 150 kW) can be maintained (and sometimes improved) if the stator is rewound using established good practice procedures.

Shops need to:

- Follow good practices of ANSI/EASA AR100 and EASA’s Good Practice Guide to Maintain Motor Efficiency

- The stator is rewound using established repair procedures.

You may opt for a higher-efficiency motor to reduce CO2 emissions and save thousands of dollars per year. All these questions still need to be asked…Do you have the funds available? is the correct motor available? etc. etc.

Are There Funds for Replacing the Motor?

At the end of your assessment, you may end up with a coin toss of a decision still. If all things are equal it may come down to whether or not you have the budget for a new motor. When we are talking about a 600HP motor, for example, we could be looking at $20-$25K in difference, which is not insignificant of course.

Is There a Suitable Replacement Available?

This can be a scary question given some of the supply chain issues we have seen in the last few years, but naturally, it is an important question that must be asked and answered.

Common motors under 200HP are typically available, either at your local Motor Shop or at a Manufacturer’s warehouse. Larger motors or those with special features can have delivery times exceeding 6 months – this lead time most operations cannot wait that long, so repairing is the only option.

Some customers may choose to repair their existing motor and order that new motor. Once that new motor comes in, they swap it out and then use the older repaired motor as a spare. We recommend having a spare for pieces of equipment that you cannot afford to have not run – the ones that cost you $10k, 100K per hour when they are not running. An $8000 spare motor is relatively inexpensive if it gives you peace of mind and can save you $8000 an hour in production losses.

The motor in question may have been modified or has special features that affect the replacement price or availability. We will often see motor requests come in where it has either been produced to an OEM Specification or has been modified for a specific mounting scenario, or a motor is older and has been discontinued. The only option may be to repair this motor. That means removing it from service and losing that piece of equipment for several days while it is repaired – hopefully without further delays.

Electric Motor Repair or Replace: A Conclusion.

Situation A: You have determined that the motor you needed to replace or repair was being used in an appropriate manner, the rotor and stator are in good condition as are the other mechanical components, there was no catastrophic failure and the cause of the failure was normal wear and tear or lack of maintenance. All signs point to repairing the motor, after all this is an IE3 Motor (NEMA Premium), and after reading this article you know that energy efficiency can be maintained or even improved through repair. Lastly, there is a replacement available, but the cost of this new motor is more than double the cost of the repair will be.

Repairing this motor is going to cost $2500. Buying a new motor will cost $8000. The new motor has a slightly higher efficiency, it will pay for itself over several years. The repaired motor has another 5-8 years in it before it fails again.

Solution: Repair the Motor. The new motor route isn’t the worst idea, however, if you have other motors that are more in need of being replaced then your budget should likely go to that motor.

Situation B: The motor was being used in a suitable manner, and the stator is in decent condition – not great, but decent. There was no catastrophic failure, however, this is a much older motor and therefore has a lower efficiency, there are multiple reasons for failure which means the repair cost is going to be much higher, still less than a new motor though. The replacement motor is available and can be delivered and installed within 2 days.

Repairing this motor is going to cost $5500. Buying a new motor will cost $8000. But the new motor has a higher efficiency, meaning over time it will pay back this difference. The repaired motor has another 3 years in it before it suffers catastrophic failure. The new motor will give you 15 years.

Solution: Buy a new motor. The repair costs are close to the cost of a new motor AND you will save money on energy costs over a relatively short period of time (varies by motor size, application, and energy costs in your region).

Leave a Reply