Understanding Explosion-Proof Motors

Defining Explosion-Proof Motors

Explosion-proof motors are specially engineered electric motors that prevent the ignition of external flammable substances. Unlike standard motors, these units are constructed to withstand and contain explosions within their enclosures, ensuring the safety of both the machinery and personnel.

The Need for Explosion-Proof Motors

The presence of combustible elements in various industries necessitates the use of explosion-proof motors. From refineries to mining operations, these motors are indispensable in preventing sparks and arcs that could trigger catastrophic fires or explosions.

What is a hazardous Location?

Hazardous locations are characterized by the presence of flammable gases, vapors, combustible dusts, or fibers that pose a potential risk of ignition due to electrical equipment, including electric motors. These locations are categorized based on factors like the nature and frequency of hazardous substances, which are vital in determining the appropriate electric motor for the environment.

Classifications and Protection

Class I: Flammable Gases and Vapors

In environments where flammable gases or vapors are present, such as chemical plants, oil refineries, or paint booths, adhering to Class I classifications is imperative. These classifications encompass divisions and groups that categorize the level of risk associated with specific hazardous substances.

Class II: Combustible Dust

Industries handling combustible dusts like grain mills, flour processing, and metal grinding must adhere to Class II classifications. Similar to Class I, these classifications involve divisions and groups that dictate the level of protection required for electric motors operating in these environments.

Division System: The Specific Hazard

In addition to classes, explosion-proof motors are categorized using divisions, which specify the likelihood of hazardous substances being present. Division 1 refers to areas where such substances are consistently present, while Division 2 indicates their occasional presence.

Ingress Protection (IP) Ratings

An IP rating indicates the motor’s resistance to dust and moisture, a crucial consideration in hazardous locations. It consists of two digits: the first denotes solid particle protection, while the second pertains to liquid ingress protection. For instance, a motor with an IP65 rating ensures high protection against dust and water jets.

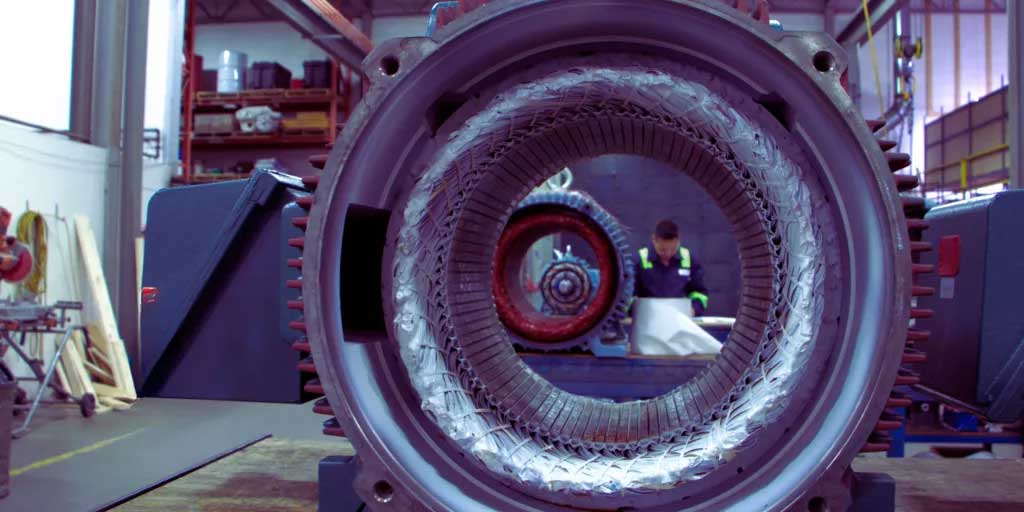

Components of an Explosion-Proof Motor

Enclosures: Shielding against Explosions

The enclosures of explosion-proof motors are built robustly with durable materials, effectively containing explosions within the motor’s confines.

Sealing: Preventing External Elements

Sealing mechanisms in explosion-proof motors prevent external elements from infiltrating the motor, maintaining its integrity.

Thermal Protection: Avoiding Overheating

Thermal protection systems ensure that the motor doesn’t reach temperatures that could potentially ignite hazardous substances.

Selecting the Right Explosion-Proof Motor

Assessing the Hazardous Environment

When selecting an explosion-proof motor, evaluating the specific hazardous conditions of the environment is crucial for making the right choice.

Motor Size and Power

The size and power of the motor must be tailored to the demands of the application to ensure optimal performance and longevity.

Efficiency and Performance

Choosing an explosion-proof motor with high efficiency not only reduces energy consumption but also contributes to a safer work environment.

Applications of Explosion-Proof Motors

Petrochemical Industry

In refineries and chemical plants, explosion-proof motors power critical equipment, safeguarding against hazardous substances.

Mining Operations

Mines often have an abundance of combustible dust; explosion-proof motors are a cornerstone for safe mining operations.

Pharmaceutical Manufacturing

The pharmaceutical industry, which demands stringent safety measures, benefits from, and is often required to use, explosion-proof motors in maintaining a secure production environment.

Conclusion

In conclusion, the selection of electric motors for hazardous locations demands a meticulous approach that encompasses classification, protection, temperature considerations, horsepower, enclosure type, and IP ratings. By adhering to these factors and seeking expert guidance, you can ensure the seamless and safe operation of electric motors in these critical environments. Our commitment to empowering your decision-making process enables you to not only meet safety standards but also optimize performance and efficiency, bolstering your industrial operations in hazardous locations.