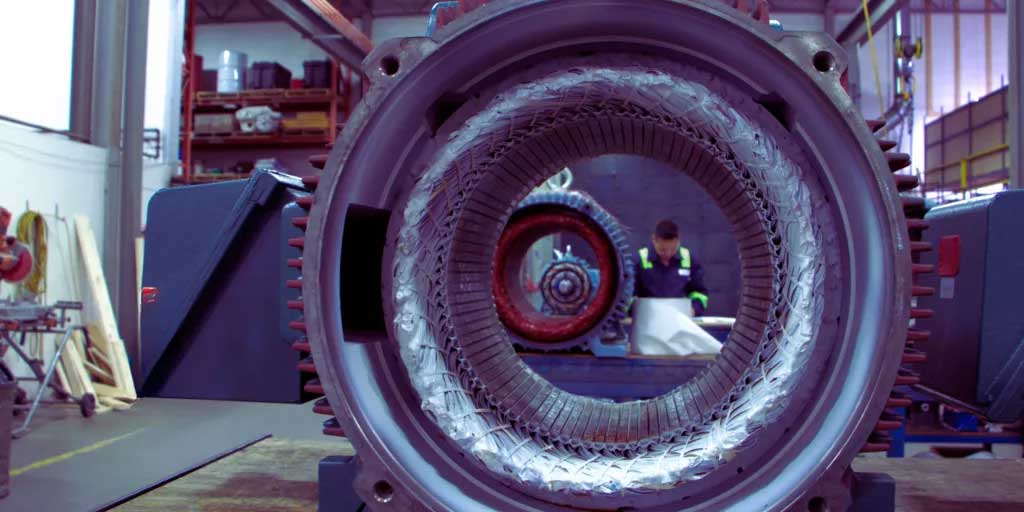

Motor Repairs

We handle the electric motor repair process from start to finish. Before we can quote you what the repair will cost, we first need to do a thorough inspection of the motor. While there is a cost to this, it will help us determine if it is more cost-effective to repair or replace. Our technicians will disassemble the motor, repair or replace any damaged components, and reassemble it to its original specifications. By following our service process we will ensure that you know what is happening and what your options are along the way.

Motor Re-magnetizing

Rewinding and re-magnetizing are critical components of electric motor repair and Maintenance. Our team of experts will rewind your motor to ensure optimal performance and extend its lifespan. We also offer re-magnetizing services to restore the magnetic field to its original strength.

Motor Testing and Diagnosis

Our technicians will diagnose the problem with your motor and test it to determine the root cause of the issue. This enables us to determine the best course of action to take and provide an accurate estimate of the repair costs.

Dynamic Balancing

Dynamic balancing is a critical step in the repair process that ensures that the motor runs smoothly and efficiently. Our technicians will perform this service to ensure that your motor operates with minimal vibration and maximum efficiency.

Before you repair know these things…

Age of the Motor

The motor may be older and repairing it solves your problem today but upgrading to a new motor may allow for more efficient operation of your equipment.

HP of the motor

Lower HP motors are cheaper to replace but that doesn’t necessarily mean they are cheaper to repair compared to a higher HP motor. Replacing the motor may be easier and cheaper than repairing it.

Replacement Cost

Sometimes, a new motor is more cost-effective than repairing the existing one, and maybe only 20-30% (blog post Idea to link to) more than the repair cost. If a new motor is only 20-30% more than repairing the existing motor, it would usually be our recommendation to replace rather than repair it.

Repair Cost

The cost of repairing the motor combined with the age of the motor and factoring in the cost of a new motor is likely going to help determine the best route. Generally speaking, if the cost of repairing is 60-70% of a new one, it makes more sense to replace it.