Bearing Modifications

Bearings are vital to motor reliability. We offer tailored modifications to improve durability and meet specific performance needs.

- Insulated Bearings: Protect against bearing currents and fluting in VFD applications. Insulated bearings extend life and prevent premature failure.

- Ball-to-Roller Bearing Conversion: Upgrade to roller bearings for better load handling in heavy-duty or high-radial-load applications.

- Roller-to-Ball Bearing Conversion: Switch to ball bearings for quieter, more efficient operation in moderate-load, high-speed systems.

Motor RTDs (Resistance Temperature Detectors)

RTDs allow accurate temperature monitoring for predictive maintenance and motor protection.

- Winding RTDs: Installed in windings to detect overheating and safeguard insulation.

- Bearing RTDs: Monitor bearing temperatures to catch issues like lubrication failure or misalignment early.

Motor Shaft Customizations

We modify motor shafts to match your exact application.

- Shaft Replacements & Upgrades: Use tougher materials, replace damaged shafts, or extend shaft length for custom fits.

- Encoder & Stub Shaft Options: Add encoders or stub shafts for closed-loop control and feedback systems.

- Shaft Modifications: Shorten or machine shafts for space constraints or coupling changes.

Modify For Vertical Use

Adapt horizontal motors for vertical use with drainage, safety, and structural adjustments.

- Add lifting lugs

- Install drip covers

- Remove base feet

- Reposition drain holes

Auxiliary Box Modifications

Customize auxiliary boxes for sensors or terminal arrangements.

- Resize or relocate boxes

- Add terminal blocks

CSA Certified Modifications

We provide CSA-certified upgrades for Class I, Div 1 hazardous locations.

- Install space heaters to prevent condensation

- Add explosion-proof flanges

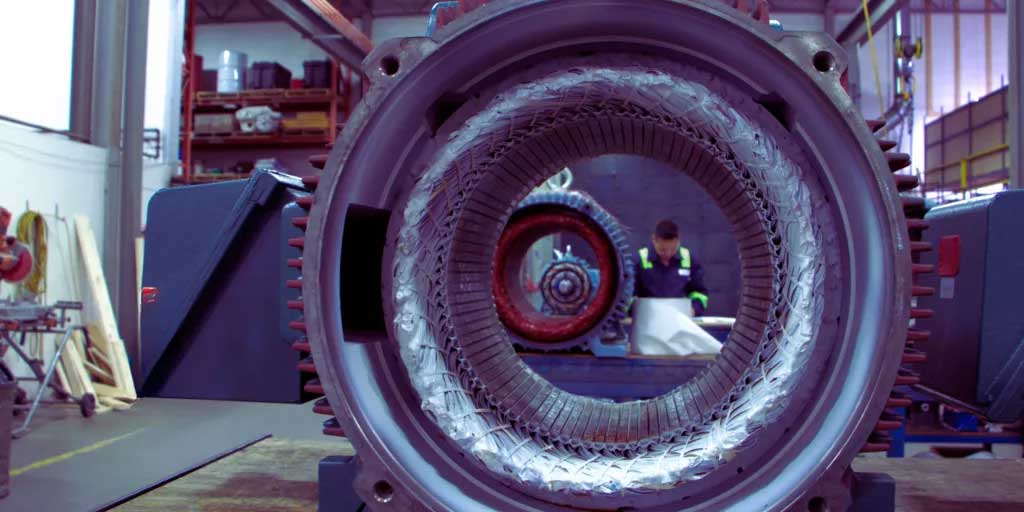

Other Motor Modifications

At Universal Rewind, we can modify your electric motor to meet most applications. To get started on your project, contact our sales team.