Have you ever asked yourself, “What is an electric motor or gearbox service factor?” or “Why is service factor important?” Or maybe you are wondering why your plant is burning through motors and gearboxes at a non-typical pace. This article will give you a better grasp of this concept and its importance to your operation. We’ll explain what it is, how it’s calculated, and why it matters. So, if you need to know more about electric motor service factors, keep reading!

Service factors measure the performance of motors in industrial settings. You can calculate the power of an electric motor in relation to its size to determine the service factor. This helps you decide if the motor can handle a specific workload or not.

Understanding service factors is essential for food processing plants, aggregate pits, and any other operation that rely on motors and gearboxes for helping move product. Knowing the workload capacity of a motor lets companies plan their operations more efficiently and cost-effectively. Additionally, it helps them decide which type of motor or motor reducer is most suitable for their needs.

What is Service Factor?

According to the EASA Technical Manual and NEMA MG1, the definition of service factor is “A multiplier which, when applied to rated power, indicates a permissible power loading that may be carried under the conditions specified for the service factor.” In other words, it shows how much more power a motor can handle than its rated power.

Put simply, any increase in load increases the current. This overload will raise the motor’s operating temperature, which will in turn reduce its expected lifespan. Factors that can contribute to “overload” are motors that start and stop frequently, cyclic loads, high peak loads, vibration, high duty cycles (i.e. running 24 hours/day), and high ambient temperatures. These high-stress environments can greatly accelerate wear and tear on the motor. This is where working with your local electric motor experts will benefit you; they will be able to advise you on the correct product with the appropriate service factor.

What is Gearbox Service Factor?

The gearbox service factor is the ratio between the horsepower that a gearbox is rated to handle and the horsepower required for the application. In practical terms, it defines a performance safety margin that may be required by incredibly demanding tasks to help ensure long-lasting and trouble-free operation.

When choosing an industrial gearbox, it’s essential to account for typical usage and operating demands. You can do this by identifying hours per day usage – this will vary depending on HP, Ratio, and overall torque outputs. Consulting with a certified distributor, like Universal Rewind, will ensure you select the appropriate gearbox; one that won’t experience rapid wear and tear or premature failure, costing your business lost productivity and parts replacement.

What is Service Factor in relation to Electric Motors?

Service Factor, in the context of electric motors vs. gearboxes, refers to the capacity of a motor to operate efficiently beyond its rated capacity for short periods. It’s an essential parameter to consider when evaluating the resilience and durability of a motor or any equipment driven by it. While the term might sound straightforward, it carries serious implications for various applications.

It’s important to distinguish the difference between Service Factor and overload capacity. The overload capacity is the motor’s ability to withstand occasional overloads without sustaining damage. Service Factor extends the motor’s continuous operating capability under non-standard conditions. In simpler terms, it’s like a safety buffer that allows the motor to perform optimally even when subjected to intermittent spikes in demand.

Going beyond that overload capacity more often can, and most likely will, result in a service life that is much shorter than expected. Choosing a motor with the appropriate Service Factor plays a pivotal role in enhancing the lifespan of equipment and minimizing downtime, translating to significant cost savings over time.

Why is Service Factor Important?

Service Factor is important because without considering it you are going to burn through motors or gearbox with greater frequency.

Selecting the appropriate gearbox or motor while considering service factors will greatly impact the longevity of your equipment – increased efficiency + reduced downtime = more profit.

The National Electrical Manufacturers Association (NEMA) states that “A motor operating continuously at any service factor greater than 1.0 will have a reduced life expectancy as compared to operating at its rated nameplate horsepower. Insulation life and bearing life can be reduced by the service factor load”.

There are several factors that can lead to overload – usually, this is the result of the increase in motor winding temperature. Mechanical overload (moving heaving materials), poor ventilation, low voltage, or high ambient temperature are just a few of the root causes leading to overload. For every 10ºC, the motor winding expected is reduced by one-half.

For gearboxes, a service factor of 1.0 likely means it is in operation for under 5 hours per day. Using a gearbox for longer than 5 hours per day on a regular basis, with this SF rating, will significantly reduce the lifespan of the product. A service factor of 2.0 indicates a gearbox that can handle a much longer operational time period. The actual hours of the day will vary but err on the side of caution today to save yourself headaches tomorrow.

When these considerations are taken into account, electric motors can be properly selected and sized for any application ensuring optimal performance, longevity, and safety.

How To Calculate Service Factor

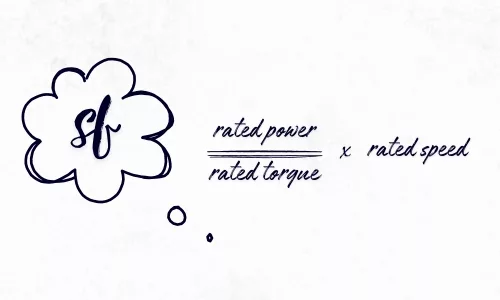

Now that we understand why SF is so critical, let’s take a peek at how it’s calculated. The service factor can be determined by a formula that factors in the electric motor’s speed, torque, and power. This equation is usually represented in the following way: Service Factor = Motor Rated Power/Motor Rated Torque x Motor Rated Speed. This formula gives a numerical representation of the motor’s capability to take on an overload for a certain period without causing damage or failure. The service factor rating would also be noted in the motor data pack.

The higher the service factor, the more dependable and efficient the motor will be under extended usage. The service factor for different kinds of motors and gearboxes can differ greatly based on their construction, size, and other design features. Understanding how you are using the motor or gearbox will ensure that we, or your local shop, is sourcing the most appropriate product.

Conclusion

Overall, understanding and correctly calculating your gearmotor, reducer, gearbox, or electric motor’s service factor is an integral part of ensuring its proper operation and efficiency over a long period of time. Taking the time to familiarize yourself with this calculation can save money and reduce operational downtime.

Leave a Reply